|

Attic pull-down ladders, also called attic pull-down stairways, are collapsible ladders that are permanently attached to the attic floor. Occupants can use these ladders to access their attics without being required to carry a portable ladder.

Relevant Codes The 2009 edition of the International Building Code (IBC) and the 2006 edition of the International Residential Code (IRC) offer guidelines regarding attic access, although not specifically pull-down ladders. Still, the information might be of some interest to inspectors. 2009 IBC (Commercial Construction): 1209.2 Attic Spaces. An opening not less than 20 inches by 30 inches (559 mm by 762 mm) shall be provided to any attic area having a clear height of over 30 inches (762 mm). A 30-inch (762 mm) minimum clear headroom in the attic space shall be provided at or above the access opening. 2006 IRC (Residential Construction): R807.1 Attic Access. Buildings with combustible ceiling or roof construction shall have an attic access opening to attic areas that exceed 30 square feet (2.8m squared) and have a vertical height of 30 inches (762 mm) or more. The rough-framed opening shall not be less than 22 inches by 30 inches, and shall be located in a hallway or readily accessible location. A 30-inch (762 mm) minimum unobstructed headroom in the attic space shall be provided at some point above the access opening. Tips that inspectors can pass on to their clients:

In summary, attic pull-down ladders are prone to a number of defects, most of which are due to improper installation.

0 Comments

Sump pumps are self-activating electrical pumps that protect homes from moisture intrusion. They are usually installed below basement or crawlspace floors to remove rising groundwater and surface runoff before it has a chance to seep into the home. Accumulated water can cause interior damage and encourage the growth of mold, mildew, and fungus. Pumps should be maintained and equipped with all necessary components in order to ensure their reliability.

Types of Sump Pumps

Inspectors should check for the presence of the following:

Discharge Location Insideout inspectors are not required to check for a proper discharge location. They can note an improper discharge if they see it, but searching outdoors for the discharge is not recommended. The following is good general information that can be passed on to the homeowner:

In summary, sump pumps are used to remove excess water from homes that would otherwise cause property damage. There are multiple types, but they all monitor water levels and ensure that they do not rise higher than predetermined levels. Proper maintenance and inspection will ensure pump efficiency and prolong their lifespan. InsideOut Home Inspectors are required to inspect the gutters and downspouts as part of the roof portion of the home inspection. Some important factors a home inspector should consider include:

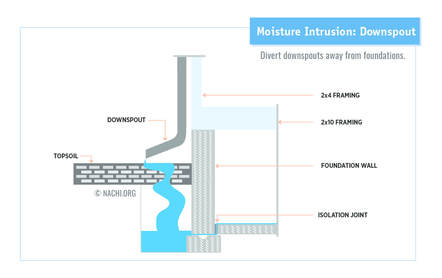

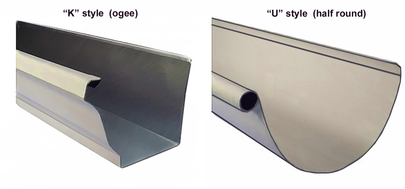

A few inches of rain falling on the roof of a house can produce several thousand gallons of water runoff. This runoff must be channeled away from the home's foundation. Otherwise, the excess water can quickly saturate the soil surrounding the building and wick through the foundation to the interior. (See Figure 1 below.) Once inside, this moisture can lead to a variety of problems, including mold and wood rot. Excess moisture can also cause indoor air quality problems. Figure 1: If not drained away from the house, the volume of water coming off a roof in a large rainstorm can quickly saturate the soil and wick through the foundation into the interior of the building. Gutter System Basics Gutter systems consist of two parts: 1) gutter channels that run horizontally along the roof edge to collect runoff; and 2) the downspouts that carry the collected water to grade level. Roofing gutters should slope down toward the downspout at the rate of 1/16-inch per foot, or 1/4-inch per 5 to 10 feet. An angle less than this won't allow water to move effectively, and much more of an angle will cause the water to move at too great a speed, potentially resulting in overflow over end caps and corners. In terms of standards, InsideOut home inspectors are not required to measure the amount of gutter slope. To do it accurately would be time-consuming, would require a transit or water level, and would exceed InterNACHI's Standards of Practice. A more practical approach is to make sure that all gutters slope toward the downspout. In judging adequate slope, look for signs of standing water in portions of the gutter away from the downspout, and eyeball the margin against the fascia. Gutter channels are typically available in 4, 5, and 6-inch sizes. They are referred to by their shape: there are K-style gutters (also known as "ogee" because the shape resembles this molding type); and U-style gutters (or half-round), as shown in Figure 2 below. The style differences are principally aesthetic; there is no substantial difference in performance. Larger sizes conduct more water at a faster rate, provided that there are enough downspouts to drain the gutter channels without overflowing. Figure 2: Standard gutter styles found in building supply centers include the K and U styles. The difference is purely aesthetic. (Image courtesy of the U.S. Dept. of Energy's Building America Solution Center.

Downspout Basics Most downspouts are made of the same material as the gutter system, so they tend to suffer from similar problems, but with a few twists -- especially in the area of mechanical damage from proximity to high-traffic areas. Downspouts should be inspected for:

The following are some climate-specific considerations for different types of gutter systems:

Inspectors can relay the following tips to their clients to help them properly and safely maintain their home's gutter system:

The home inspector should also explain to his clients the importance of a properly functioning gutter system, and the potential problems that an undersized or damaged system can create. This article was sourced from the U.S. Department of Energy and InterNACHI®. Homeowners may use a generator to supply electricity to their home in the case of a power outage, either out of necessity or convenience. Inspectors may want to know about generators and the potential hazards they present when improperly wired or utilized. Generator Types There are two main types of generators: permanently installed, standby generators; and gasoline-powered, portable generators. Standby Generators Standby generators typically operate on natural gas or liquid propane. They remain fixed in place outside the home and are designed to supply on-site power to specified circuits through a home's electrical wiring. These generators work in tandem with a manual or automatic transfer switch, which automatically detects an interruption in grid-powered electricity and subsequently transfers over electrical input to the generator.

Some advantages of standby generators are as follows:

Gasoline-powered, portable generators are typically smaller in size and power capacity than permanently installed generators. They are designed so that corded electrical devices may be plugged directly into them. Advantages to portable generators are as follows:

Inspecting A Generator

InsideOut inspectors check for the following:

In summary, generators can be lifesavers during a power outage, but they present serious health and safety concerns if they are not installed and used properly. While you can’t predict the lurking dangers in an unfamiliar home, its age offers clues about what you can expect to encounter. Older homes, especially those that have remained in the same hands for much (or all) of their lifetime, are often plagued by a common set of defects that InsideOut inspectors and potential home buyers may want to learn about. Some of the more prevalent issues of older homes are as follows.

wiring is acceptable, aluminum will generally become defective faster than copper due to certain qualities inherent in the metal. It can be identified by its color or the labels “CO/ALR,” “aluminum” and “AL”;

Arc-fault circuit interrupters (AFCIs) are special types of electrical receptacles or outlets and circuit breakers designed to detect and respond to potentially dangerous electrical arcs in home branch wiring.

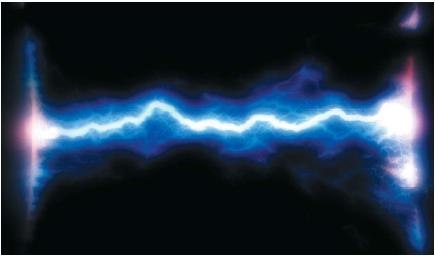

What is an arc? When an electric current crosses an air gap from an energized component to a grounded component, it produces a glowing plasma discharge known as an arc. For example, a bolt of lightening is a very large, powerful arc that crosses an atmospheric gap from an electrically charged cloud to the ground or another cloud. Just as lightning can cause fires, arcs produced by domestic wiring are capable of producing high levels of heat that can ignite their surroundings and lead to structure fires. According to statistics from the National Fire Protection Agency for the year 2005, electrical fires damaged approximately 20,900 homes, killed 500 people, and cost $862 million in property damage. Although short-circuits and overloads account for many of these fires, arcs are responsible for the majority and are undetectable by traditional (non-AFCI) circuit breakers. Where are arcs likely to form? Arcs can form where wires are improperly installed or when insulation becomes damaged. In older homes, wire insulation tends to crystallize as it ages, becoming brittle and prone to cracking and chipping. Damaged insulation exposes the current-carrying wire to its surroundings, increasing the chances that an arc may occur.

Where are AFCIs required? Locations in which AFCIs are required depend on the building codes adopted by their jurisdiction. The 2006 International Residential Code (IRC) requires that AFCIs be installed within bedrooms in the following manner: E3802.12 Arc-Fault Protection of Bedroom Outlets. All branch circuits that supply120-volt, single-phase, 15- and 20-amp outlets installed in bedrooms shall be protected by a combination-type or branch/feeder-type arc-fault circuit interrupter installed to provide protection of the entire branch circuit. Exception: The location of the arc-fault circuit interrupter shall be permitted to be at other than the origination of the branch circuit, provided that:

The National Electrical Code (NEC) offers the following guidelines concerning AFCI placement within bedrooms: Dwelling Units. All 120-volt, single phase, 15- and 20-ampere branch circuits supplying outlets installed in dwelling unit in family rooms, dining rooms, living rooms, parlors, libraries, dens, sun rooms, recreation rooms, closets, hallways, or similar rooms or areas shall be protected by a listed arc-fault circuit interrupter, combination-type installed to provide protection of the branch circuit. Home inspectors should refrain from quoting exact code in their reports. A plaintiff's attorney might suggest that code quotation means that the inspector was performing a code inspection and is therefore responsible for identifying all code violations in the home. Some jurisdictions do not yet require their implementation in locations where they can be helpful.

allowing its contents to spoil. There are a few procedures an electrical contractor can perform in order to reduce potential “nuisance tripping," such as:

Arc Faults vs. Ground Faults It is important to distinguish AFCI devices from Ground Fault Circuit Interrupter (GFCI) devices. GFCIs detect ground faults, which occur when current leaks from a hot (ungrounded) conductor to a grounded object as a result of a short-circuit. This situation can be hazardous when a person unintentionally becomes the current’s path to the ground. GFCIs function by constantly monitoring the current flow between hot and neutral (grounding) conductors, and activate when they sense a difference of 5 milliamps or more. Thus, GFCIs are intended to prevent personal injury due to electric shock, while AFCIs prevent personal injury and property damage due to structure fires. In summary, AFCIs are designed to detect small arcs of electricity before they have a chance to lead to a structure fire. The Dangers of Mold Molds produce allergens, which are substances that can cause allergic reactions, as well as irritants and, in some cases, potentially toxic substances known as mycotoxins. Inhaling or touching mold or mold spores may cause allergic reactions in sensitive individuals. Allergic responses include hay fever-type symptoms, such as sneezing, runny nose, red eyes, and skin

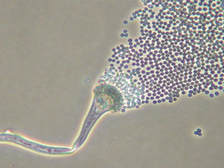

Carpet at Risk Carpeting is an area of the home that can be at high risk for mold growth. In order to grow, mold needs moisture, oxygen, a food source, and a surface to grow on. Mold spores are commonly found naturally in the air. If spores land on a wet or damp spot indoors that contains dust for them to feed on, mold growth will soon follow. Wall-to-wall carpeting, as well as area rugs, can provide an ample breeding ground for mold if conditions are right. At especially high risk for mold growth are carpeting located below ground level in basements, carpet in commonly moist or damp climates, and carpet that has been wet for any period of time. Identifying Mold in Carpeting Just because mold is not immediately apparent or visible on a carpet's surface does not mean that mold growth is not in progress. In fact, mold will probably only be visible on the surface of carpets in unusually severe cases of growth, such as carpet damaged in flooding that has remained wet for some time. InsideOut Inspections can detect specific types of mold spores by using state of the art equipment to pull air samples from your home. The following are some examples of identifiable instances where mold growth has occurred or is likely to occur:

The best method for combating mold is to not allow mold growth in the first place. The best way to do so is by ensuring that conditions conducive to growth do not exist. Below are some ways to prevent mold growth in carpets.

In many cases, if mold has grown on carpet, cleaning will not be possible. If growth has occurred on more than one area of the carpet, or if there is a large area of growth, the carpet will probably need to be replaced.

About 24 hours is a reasonable amount of time to wait after testing to be sure that wider cleaning will not discolor or damage the carpet.

Another option in instances where mold growth is not widespread is to remove the ruined section of the carpet. If cleaning has been attempted unsuccessfully, the area of mold growth may be removed and replaced with a patch of similar carpet. Of course, this will only work in situations where aesthetics are not a big concern, since exactly matching the patch to the original carpet may be difficult and the seam may be visible. If mold has grown in more than one area of the carpet, or if the area of growth is larger than a couple of feet, this will probably not be an effective method of mold removal. As with all areas of the interior at risk for mold growth, prevention is the best method of control for carpet mold. Eliminating high-moisture conditions and preventing the risk of flooding or standing water will reduce the possibility of growth. Inspectors will want to know where to look for and how to identify mold growth in carpeting. It is also helpful to know how to determine if carpet should be replaced, or whether there is a possibility of cleaning and saving it. Carpeted bathrooms are bathrooms that have carpeted floors instead of traditional floor surfaces, such as tile or vinyl. Despite their tendency to foster mold and bacteria, carpets are sometimes installed in residential bathrooms for aesthetic purposes.

Disadvantages of Carpets in Bathrooms

The pad beneath the carpet may soak up large amounts of moisture. Some of the common ways that carpets may come into contact with moisture in bathrooms include:

In addition to potential mold growth beneath the carpet, bacteria can accumulate in carpeting that surrounds the toilet. Bacteria are contained in urine, which can be accidentally deflected onto the carpet. The following are recommendations that InterNACHI inspectors can pass on to clients who are experiencing urine- or moisture-related problems with their bathroom carpet:

In summary, carpets installed in bathrooms can trap moisture and urine, substances that can cause structural damage and health problems. Ceramic tile and stone are popular flooring materials, but each is subject to damage if not properly maintained.

In summary, ceramic and stone can be superb flooring materials, but water, acid, improper installation, and other adverse conditions may create defects.

Condensation, also called sweating, forms on building materials when the temperature drops below the dew point, which is the temperature at which droplets of water vapor are forced so closely together that they coalesce into liquid water. Because of their characteristic thermal conductivity, components made of metal are usually the first places where condensation will appear in a building.

Where does condensation typically form?

Metals also vary in their thermal conductivity. Thus, they tend to cause water vapor to condense. Inspectors can be aided by a rule of thumb that states that a metal’s ability to transfer heat (and, therefore, create condensation) is roughly equal to that metal’s electrical conductivity. Electricians and some inspectors may know that, of all metals, copper is the second-best conductor of heat and electricity, meaning that it’s more likely to respond to a brief burst of cool water or air than other metals, such as steel or lead. The metal with the greatest conductivity is silver, but it’s far too expensive to be used in ordinary construction.

In summary, condensation will form on cold surfaces if certain precautions are not taken. If left unmitigated, it can lead to moisture-related problems that can affect structural components, as well as the occupants' health. |

InsideOut Team

This blog is to help people better understand their home inspection. It is filled with great in depth advice. If you'd like a topic covered just send us an email on what you need more information on! Archives

August 2023

Categories

All

|

AboutThe best home & commercial building inspection company in Michigan. Serving Southeast Michigan, Northwest Ohio, Northern Michigan and surrounding areas.

|

Address8314 Whiteford Center Rd Ottawa Lake, MI

49267 1354 W Bear Lake Rd NE Kalkaska, MI 49646 |

ConnectSE Michigan: 734-224-0342

N Michigan : 231-714-6880 NW Ohio: 419-215-3856 Office@insideoutinspectionsplus.net M-F: 7AM - 8:30 PM Saturday: 7AM - 8:30 PM Sunday: 7AM - 8:30 PM |

Social Media |

Resources |

© 2023 InsideoutInspections.net. All Rights Reserved.

RSS Feed

RSS Feed